Easy Wood Laser Cutting Machine That Are Air Cooled

A wood laser cutting machine is both simple and complex. It works in three axes. The tool processes material, cuts or engraves using two basic parameters – power and speed. At the same time, a laser cutter is more complex than all others are. This peculiarity arises because of the huge list of materials it is capable of processing.

How to select a laser cutting machine for cutting wood for home use?

If you choose the wrong laser cutter for woodworking, you can encounter many negative factors. Different categories of machines are available today. There are simpler models and professional tools designed to work 24/7.

An inappropriate machine can lead to the fact that the customer runs the risk of not being able to make some complex products. This often occurs due to the wrong choice of:

- The size of the working area;

- The power of a co2 tube;

- The structural elements.

As a result, the laser cutter machine is not able to process a particular material. For example, if a device with insufficient rigidity, wall thickness and lack of a frame is chosen, it eliminates the possibility of working on stone or performing operations with other heavy products directly on the work table and requires a clamp truck, which the design of a budget cnc cutting machine often does not allow for.

Support and maintenance

The main negative factors that occur when a laser cutter malfunctions are breakdowns. They occur due to:

- Improper operation;

- Use of low quality components for a particular task;

- Influence of external factors.

If the machine is broken, the breakdown should be repaired in the shortest possible time. In order for the repair not to cause difficulties, it is necessary to purchase a cnc cutting machine, the components for which are produced by well-known brands.

In case a machine that is not suitable for woodcutting or the required task is selected, this will encourage users to make modifications for subsequent cnc cutting machine. This approach is unacceptable and significantly slows down the production process.

It is possible for defects to occur. In the production of laser cutter, this phenomenon cannot usually be dealt with. To avoid this, it is necessary to buy cnc wood cutting machines from well-known manufacturers.

To make sure that the product is original, you need to pay attention to the name. It should match the name of the factory. Reputable manufacturers supply components for their products. If a manufacturer cares about its reputation, it strives to avoid even small inaccuracies.

Size and power of a laser cutter for woodcutting

CNC wood cutting machines consist of a number of structural elements. They are divided into several groups:

- Tooling;

- Constructive;

- Kinematics;

- Software;

- Options.

Tooling is one of the main groups of structural elements of a cnc laser cutting machine. This category includes a co2 tube.

Most often, laser cutters allow more than one tube by power type. This means that they can be changed depending on the customer's task. The cooling of the equipment will also depend on this. Considering which tube is chosen, a chiller is purchased.

In the main bundle with the laser tube there is an ignition unit (high voltage unit). This is actually the power supply for the laser tube. It is also affected by the power of the tube. Today, manufacturers offer ignition units that can be adjusted when working on wood or other materials. However, when replacing the tube, you often have to change the high voltage unit, too. Usually machines used CO2 emitter.

The lenses can be of different diameters and have different focal lengths, which affects the size of the bridge. They are called:

- Short-focused;

- Medium focused;

- Long-focused.

If a client needs to cut thick material with a cnc cutting machine, a long-focus lens is used. When cutting wood or other material with a thickness of 4-8 mm, it is enough to use a short-focused lens. This allows working without the occurrence of taper. It is important to note that changing the optics takes the operator from a few seconds to a minute.

We are happy to advice you from the very beginning

Contact us now.

Also, the head is supplied with air, which is necessary to cool the laser cutting site or to blow out the products of combustion. The main purpose of such a system is to protect the lens from soot. Some materials can be cut without air. But then there is a chance of burning the material.

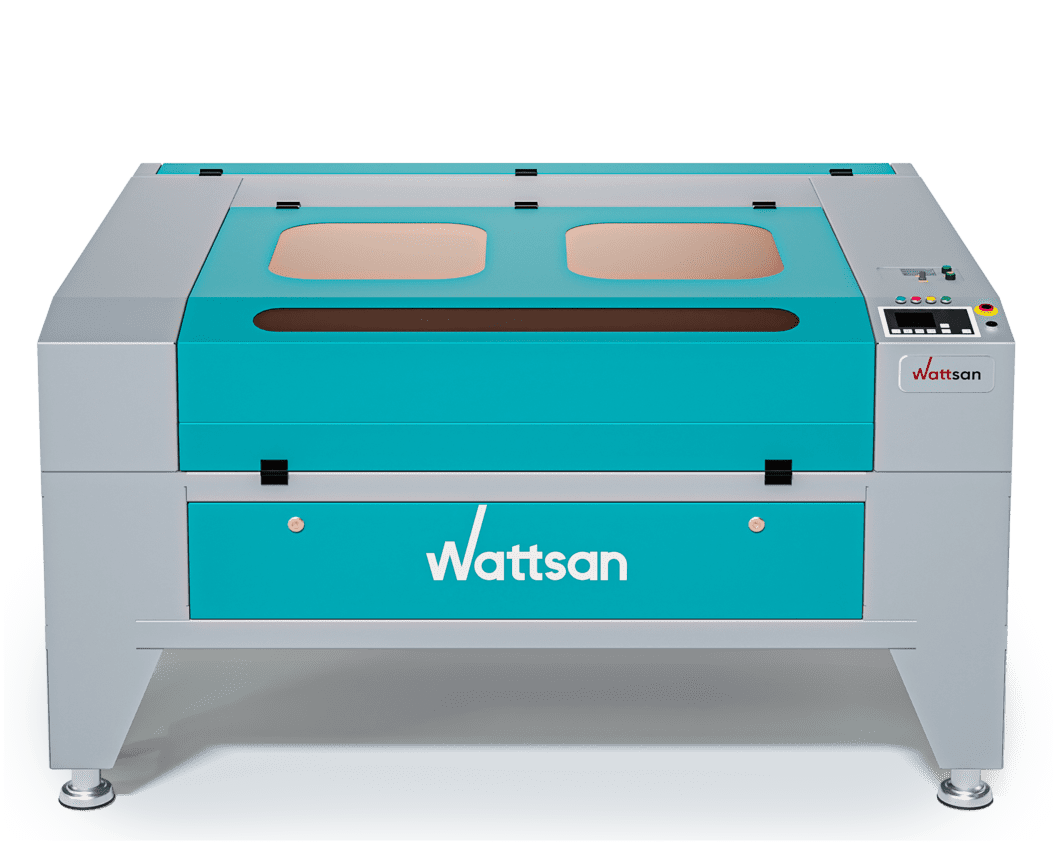

Wattsan machines for cutting wood

Wattsan machines are equipped with the function of lifting and lowering the table. It is marked with the "ST" and "LT". The function is available in cnc machines with a working area size:

- 6090;

- 1290;

- 1610.

The function is necessary for those who perform laser cutting of three-dimensional flat materials. In addition, there is an ST function. It provides a stationary table for cnc cutting. The function is required for those who cut flat materials only.

Wattsan 6090

| Work area | 900 x 600 mm |

| Tube power | 80-90 W |

| Max engraving speed | 700 mm |

| Dimensions | 1030 mm * 1490 mm * 670 mm + 315 mm (if on its wheels) |

More

Today, the most popular laser cutter for cutting, engraving, and woodworking in general is the Wattsan 60 90 LT or ST. This modification is distinguished by a unique working area, which is designed for cutting sheets of plywood. The 60 90 is so popular precisely because of its size, low price, and a large number of improvements made to it.

The thickness of the cnc machine body is the same as that of larger tools, which makes it, due to its smaller size, even more rigid and stable. The machine is equipped with a chain mechanism for lifting and lowering the table, which is driven by an asynchronous motor.

A funnel-shaped niche for garbage protects the chain from small pieces. In addition, it gives extra rigidity. The Wattsan 60 90 has an unusually durable portal and proper selection of all components.

For woodcutting, the cnc machine can be equipped with a narrower nozzle, which, with a standard compressor and a smaller cross-sectional area, gives a higher blowout. Sometimes a wide nozzle is used, which is necessary for engraving. Then the blowing capacity is slightly reduced, and the combustion residue does not stick to the material.

The Wattsan 60 90 is the most popular machine on the market. This has been achieved because of a combination of the following factors:

- Working area size;

- Price;

- Number of improvements.

The machine can be equipped with several co2 tubes. The standard version comes with an 80 W laser tube.

Wattsan 1610

| Work area | 1600 x 1000 mm |

| Tube power | 100-120W |

| Max engraving speed | 700 mm |

| Dimensions | 1410 mm * 1790 mm * 670 mm + 315 mm (if on its wheels) |

More

The Wattsan 1610 LT/ST machine allows you to cut wood with a laser with almost no pre-cutting, using a through table. A sheet can be placed on it if the final product is smaller than the size of the working area. Wattsan NC-C1612 can cut metal.

Some of the material will hang down behind the machine after pre-cutting. It can either be cut off immediately, or a sheet of plywood or wood can be pulled under the portal.

As standard, the laser cutter comes with a 100-120 W tube for laser cutting and can be equipped with both a lower power tube and a larger one depending on the thickness and required cutting speed of the cutting on wood.

The Wattsan 16 10 LT/ST machine has a large number of improvements to simplify woodcutting. In addition to the fact that all machines have proper design, they have thick walled metal bodies. Customers prefer this type of equipment because of:

- Proper construction;

- Planetary gearboxes, which significantly extends the life of stepper motors;

- Rubber belts.

Rubber belts can be pulled tighter than conventional belts and this will not cause wobble. As a result, it is possible to obtain a perfectly even edge when working on wood.

For milling wood use cnc routers.

Wattsan 2030

| Work area | 3000 x 2000 mm |

| Tube power | 100-120W |

| Max engraving speed | 500 mm |

| Dimensions | 2400 mm * 3750 mm * 800 mm |

More

The Wattsan 2030 is designed for cutting wood and other materials in full size. It will easily fit a sheet of plywood. It can be cut into the necessary elements without pre-cutting, which is unusually convenient especially when working with plywood over 6 mm thick. Thin plywood can bend somewhat, disrupting the focal length. That is why weights are often used on this machine.

Also the Wattsan 20 30 is designed to cut acrylic in full size. There is a portal in which the tube is located. It allows you to keep a small dot of a laser beam, thereby achieving excellent laser cutting quality.

The machine is equipped with 2 steppers. Some manufacturers use one engine to move the portal along Y, which is fundamentally wrong. This approach quickly leads to distortions of the portal when working on wood.

This laser cutter is not normally used for engraving, although it is capable of this. If necessary, the process will be carried out at a lower speed than on machines with a smaller working area.

The main advantage of the Wattsan 20 30 is its size. However, at the same time it is also its main disadvantage. Precisely because of its size, it costs more than analogues and is not so popular among customers. Most often it is purchased by large industrial companies.

Wattsan 6040

| Work area | 600 x 400 mm |

| Tube power | 80-90W |

| Max engraving speed | 500 mm |

| Dimensions | 765 mm * 1165 mm * 600 mm |

More

The Wattsan 60 40 is a cnc laser cutter with an 80 W laser tube. It is a desktop model for home use, which has the ability to replace the laser tube to a more powerful one due to the universal fasteners.

However normally this is not necessary since the main materials the machine cut do not exceed a thickness of 8 mm. Usually it is used to work on materials with a thickness of 4 mm.

The machine can be upgraded if needed. It happens rarely though. The laser tool has a proper structure and reinforced portal allowing working at high speed. As a rule, 50% of the operation time, this machine is used for engraving, and 50% for cutting.

Wattsan 1290

| Work area | 1200 x 900 mm |

| Tube power | 100-120W |

| Max engraving speed | 700 mm |

| Dimensions | 1410 mm * 1790 mm * 670 mm + 315 mm (if on its wheels) |

More

The Wattsan 12 90 is the most often choice for those customers who buy their first cnc laser cutter machine. It is chosen if there is a need for an industrial machine, but the budget is limited. The price for the Wattsan 12 90 is not as high as for the 16 10 one and not as low as for cheaper counterparts. The machine comes with a 100-120 W laser tube that is mostly intended for laser cutting. However, engraving is also possible on this laser equipment due to the potentiometer, which allows adjusting power to less than 10%.

Wattsan 0503

| Work area | 500 x 300 mm |

| Tube power | 60W |

| Max engraving speed | 700 mm |

| Dimensions | 650 mm * 1040 mm * 575 mm |

More

The Wattsan 05 03 laser desktop machine is one of the most popular among our clients. Its main disadvantage is a 60 W laser tube and lack of universal fasteners. It is mostly used for engraving.

Most often novice customers buy this machine with a rotary device. However we would not recommend this if you are not sure, you will process cylindrical objects. But if this is the main purpose of the purchase, it will reduce the payback period of the machine at times.

At the same time, upgrading this tool to a more powerful laser tube is quite difficult. The laser machine is the cheapest among those mentioned above. That is why it is so popular.

We are happy to advice you from the very beginning

Contact us now.

How do a laser cutting machine for woodcutting work?

In order to understand how a laser machine for woodcutting works, it is needed to learn the simple rule. It is as follows: 10 W of the laser tube power is enough to cut 1 mm of plywood. It is essential to consider this material due to the fact that plywood is the closest to wood.

This lifehack means that to cut 6 mm of plywood the user needs a 60 W laser tube. This feature must be taken into account when choosing a laser machine. But there are some nuances. For example, the tube must operate at 80% of its stated power.

As a result, the requirements have changed. To cut 6 mm of plywood, a minimum 80 W laser tube is needed. As the power of the tube increases, the processing speed will increase, too.

It is important to pay attention to cutting different types of wood. Most of them are treated the same way as plywood. The only difference is that it has adhesives. However, some types of wood are easier to cut and some are more difficult. It depends on:

- The moisture content of the wood;

- The density of the material;

- The presence of additional components, such as glue.

To understand the peculiarities of laser woodcutting, it is important to learn the details of the process.

It is based on a laser beam. It is generated in a laser tube, and then through a system of mirrors it enters directly into the laser head, in which the optics are located. The lens collects the laser beam coming into it at a minimum point. The size of this point is adjusted by the operator during the initial setting when switching on. Its size depends on the material used. The concentrated and focused beam hits the material and causes it to evaporate.

In addition, air is supplied to the laser head under pressure. It keeps the material from catching fire. The air blows off the combustion products and significantly affects the cutting frequency. With this simple method, laser cutting on wood occurs.

The cnc laser machines have two main parameters; they are power and speed. To cut any material, it is necessary to increase power and decrease speed. When engraving is carried out, the situation is reversed. To implement the procedure, you need to increase the speed and reduce the power.

The sequence for cnc laser cutting and engraving is strictly defined. Initially the engraving takes place and then the laser cuts the wood. If you do the opposite, the laser head will not recognize that the part has fallen below.

As a result, the laser machine will work on a blank spot. This is why engraving is done first and then laser cutting.

What can be done with a cnc laser cutting machine?

The equipment is versatile. It can be used to produce:

- Wooden puzzles;

- Toys;

- Prototypes;

- Other wooden goods.

When considering the scope of application, the souvenir industry deserves attention. Laser cutting or engraving can be applied either to clean wood without pre-treatment, or with a sequential drawing.

The second method is used when making magnets or wooden puzzles. Additionally, it is relevant in the production of furniture, complex items, and products with internal straight or sharp angles, which cannot be done on any other machine.

It is possible to make children's toys from wood. Due to the fact that wood is an environmentally friendly product, and laser cutting does not worsen or improve the properties of the product in the least, it has become widespread in the children's industry.

Very often the machine is used by large companies to create a prototype. It is even used in aircraft construction. Before making any large products, a prototype is created. It allows you to assess the features of the object in advance, to understand how to work on it better. The method is used when creating:

- Planes;

- Complex machines;

- Other equipment, an error in the manufacture of which will lead to high expenses.

The prototype is made of wood or plastic. The item is made directly on the laser machine. This is possible because of the extraordinary flexibility of the cnc cutting machine. This means that if the part is not satisfactory after cutting in wood, it can be redesigned almost immediately by starting the laser machine over again.

It is acceptable to use a cnc machine in conjunction with other types of equipment. For example, in the production of puzzles, the wood is initially painted, and then it is cut with cnc machine. Not only the laser but also the cnc routers is involved in the process.

Using the capabilities of the laser machine a variety of packaging is manufactured. It is made of wood. Usually the equipment is used if it is necessary to create a unique product. However, there are machines for scaling, such as the Wattsan 16 10, where two products can be done in parallel.

In other words, the machine is used everywhere for woodcutting. Often it is the only possible option for drawing or cnc cutting on wood due to the complexity of the design. Such capabilities are provided by little help from a laser beam.

Conclusions

Starting the modernization of Watson machines, we set ourselves the goal of achieving their exclusivity and making them convenient for use in the maximum possible number of spheres. Many modifications made to the machine were done after:

- Analyzing customers feedback;

- Studying the opinions of our engineers;

- Checking the results of testing.

For example, one of the world's largest wooden puzzle manufacturers has made four or five improvements to our laser woodworking machine. They affected the quality of the products and post-processing required.

We put a combination of the following factors at the top of the list:

- Use of the most reliable and high-quality components;

- Selection of parts depending on the prevalence on the market;

- Possibility of quick replacement of components.

We understand that components should not only be reliable, but also interchangeable.

The second factor that affects trouble-free woodwork is service support. At the moment it is implemented remotely.

Any Watson customer, even if they bought the machine on the secondary market, can contact our website by the serial number of the machine and get comprehensive advice on the problem that has arisen.

We do not care whom you bought your woodworking machine from. What matters to us is that you are a Wattsan customer.

Also, we are always working on the best logistics system. Our laser woodworking and engraving machines are shipped all over the world. Today, the most common users of our products are:

- Europe;

- Russia;

- Asia.

With each call from our clients, we work out the logistics better and better. In addition to standard delivery terms, in some regions we can offer both woodcutting machines from stock and delivery with the help of brokers who have already proven themselves.

Wattsan cnc machines are designed for woodworking and obtaining the highest quality product without post-processing. We are constantly improving them, allowing the client not to deal with additional cleaning of the edge and immediately send the received products for sale.

In addition, we work to ensure that the time spent on the manufacturing of the product is as short as possible. Using our equipment, you can get the most competitive products. Those who are not engaged in post-processing of products have a competitive advantage of 20-30% of the cost.

We are happy to advice you from the very beginning

Contact us now.

FAQ

Can a tree be put into a cnc machine?

No, a whole tree cannot be put into a laser machine. It is necessary to consider the size of the material to be processed. In general, working with wood is possible.

What kind of wood is suitable for laser cutting?

Most types of wood are suitable for cutting. The exception is the solid types of material. It is impractical to cut them on a cnc cutting machine. It is also better to refuse to work with highly resinous materials, hollow wood. The reason for this is that the laser beam might be defocused, which can provoke a fire.

What thickness of wood can a cnc machine cut?

This depends on the power of the co2 tube. It is worth following the rule: 10 watts of power per 1 millimeter of plywood. This means that a 100 W tube can cut 10 millimeters of plywood. For the tube to last longer, it is better to use it at 80% power.

Can a laser machine cut plywood?

Yes, it is suitable for cutting almost all types of plywood that do not emit harmful flammable substances. This is its main scope of application.

Is MDF suitable for cnc cutting?

Yes, it is, but it is worth focusing especially on the blowing. When cutting thick MDF materials with a laser, there is a lot of dust and more carbon deposits are formed. It is recommended to cut MDF no thicker than 6 millimeters.

Source: https://wattsan.com/laser-cutting-machine-wood/